When it comes to metal and steel fabrication, most contract manufacturing companies will provide you with two main options to choose from, namely tube laser cutting or bundle cut sawing. We give a brief outline of the pros and cons of each below.

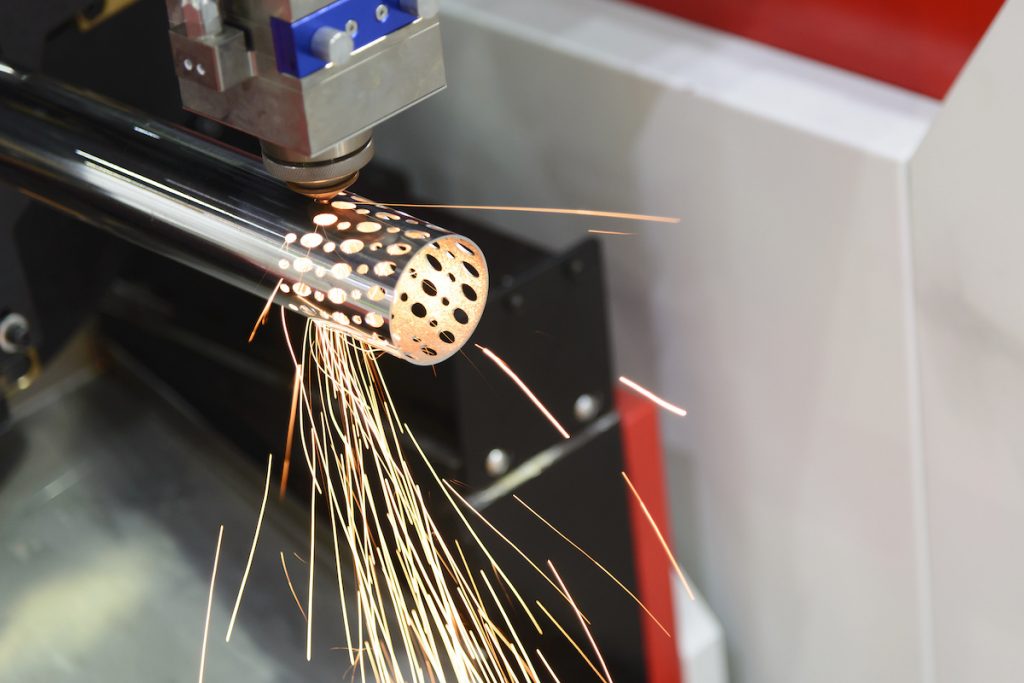

Tube Laser Cutting

Tube laser cutting is a great consideration if optimal precision is important to you. Tube laser cutting is one of the most precise options, always offering a smooth and clean result. Laser cutters are also designed to be used to cut various types of metal including stainless steel and titanium. Tube laser cutting is also often more eco-friendly (reduced waste in material movement) and more efficient than other cutting options out there, especially because it requires minimal set-up time.

The only con to consider is that tube laser cutting is usually more expensive than bundle cut sawing.

Bundle Cut Sawing

Bundle cut sawing is the more traditional method of cutting in steel fabrication and mechanical engineering applications. Once the bundle cut sawing equipment has been properly set up, the process is rather efficient. However, it definitely is not as efficient as tube laser cutting.

Ultimately, whether you opt for tube laser cutting or bundle cut sawing will depend on your individual preferences and budget constraints. The secret is to choose the right contract manufacturing company that will be able to provide you with a mix of efficiency and affordability regardless of your selection!

For information about both different cutting techniques, as well as details on mechanical engineering and steel fabrication at Rider Tool & Manufacturing Co., please do not hesitate to contact our team.