Before hiring contract manufacturing companies or any specialist to handle your steel fabrication requirements, it is imperative that you understand tight fabrication tolerances and how they may affect the quality of what is delivered to you.

-

What Are Tight Fabrication Tolerances?

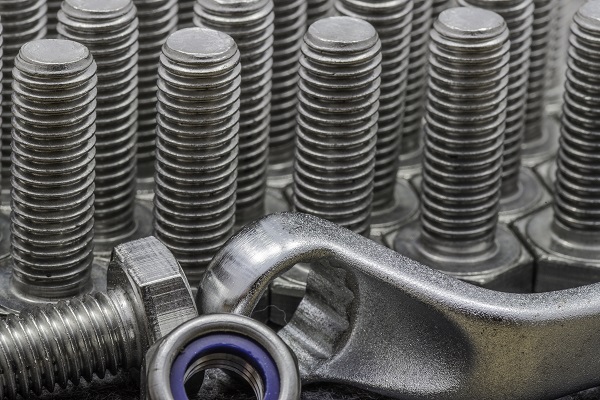

Fabrication tolerances, otherwise often referred to as engineering tolerances, refers to the amount of variation that is allowed when it comes to the physical dimensions of items, for example, in the case of mechanical engineering, the space that exists between a bolt and a nut. If fabrication tolerances are tight, it means that there is very little room, if any at all, for any variation. In short, you will need a contract manufacturing company that will be able to promise you meticulous results. This type of meticulous work can only be undertaken for professionals who boast the right amount of experience and the right tools for the job.

-

When Tight Fabrication Tolerances Are Unnecessary

In order to decide how tight your fabrication tolerances need to be, it is always advisable to consult with an experienced risk management team. They will be able to ascertain whether the same results are achievable with slightly more relaxed tolerances, or if extremely tight fabrication tolerances are essential if you are to maintain the integrity and quality of the finished product.

It is important to remember that tight fabrication tolerance, when unnecessary, may increase the cost of steel fabrication and increase the time that it takes in order to complete it. Optimizing fabrication tolerances to ensure the best quality final product, along with the lowest possible cost and turnaround times, is essential when hiring contract-manufacturing companies.

Here at Rider Tool & Manufacturing Co., we specialize in steel fabrication and mechanical engineering, with a focus on sticking firmly to our clients’ tight fabrication tolerances. For more information about us and how we can help you, do not hesitate to get in touch with our team.