The onsite installation of fabricated industrial equipment is a service that is in considerable demand among our clients. It has tremendous benefits for the client because it enables the building and installation of their equipment by a single service provider, cutting out any need for a long chain of contractors that could potentially break down at the weakest link.

Because field installation is such a complex process, it requires a few key elements to work in tandem to make it successful.

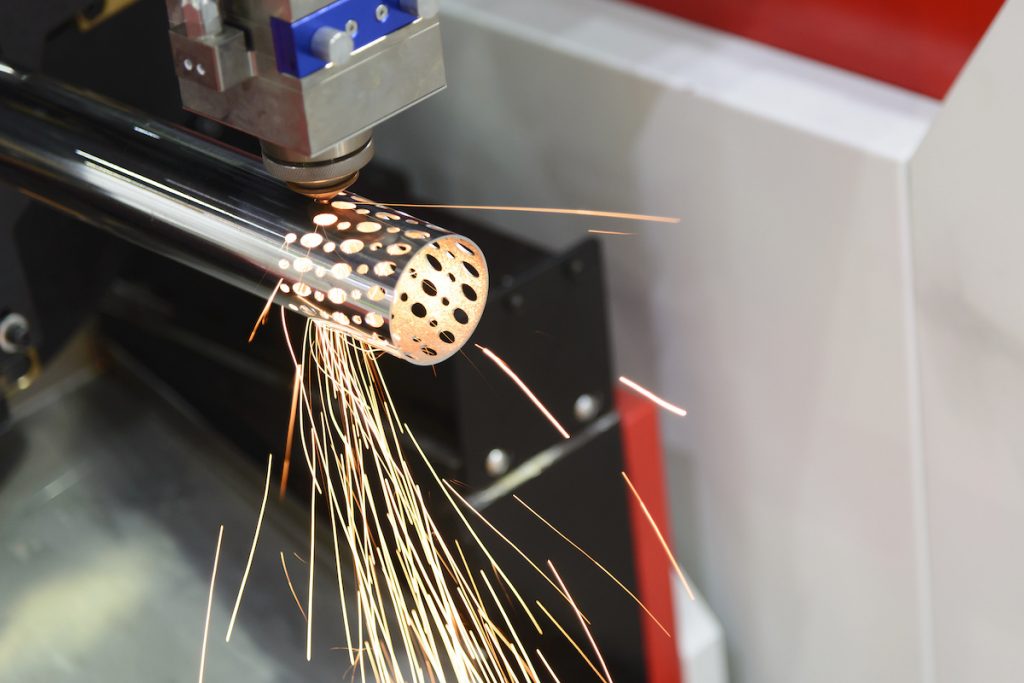

Expertise

First off, not to put too fine a point on it, you need people who know what they’re doing. From the very beginning, even as the various components are being planned, you need an expert team that understands the materials involved, the client’s needs, the processes required to fill the brief, the logistics necessary to move the components to site and what is needed to assemble and install the end product, as efficiently as possible.

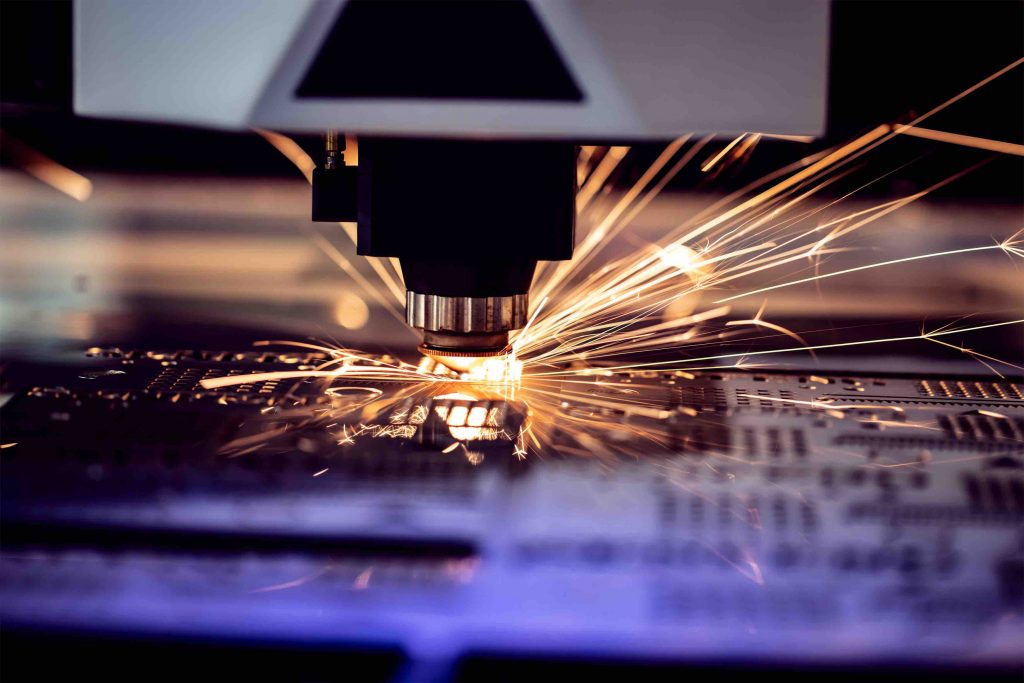

Quality Control

As important as expertise is an absolutely rock solid quality control protocol. The entire value chain, including labour, planning, parts, materials, transport and installation, must be monitored under a unifying, end-to-end quality control procedure. This ensures that each and every stage of the process is up to standard in its own right, and it also maintains consistent quality throughout the job as a whole. This is vital when working on a project with any number of variables, becoming all the more important as complexity increases.

Clear Communication

As with any value chain, field installation requires clear and unmistakable communications between all role players, both internally and between the client and service provider.

Logistical Planning

The way a job is carried out depends not only on the specifics of the job itself, but also on the distances between the fabricator’s premises and the installation site, the number, size and weight of the components involved as well as the type of transport needed. The fabricator may have to set a limit on the distances they are willing to travel to do the installation. It may be necessary, for example, to serve clients only within a 500-mile radius. Anything beyond the designated limit could make the costs in outlay, transport and manpower unfeasible.

Keeping it Simple

Simplicity is the key to handling complexity. Whatever steps can be eliminated without adversely affecting the outcome should be bridged or dispensed with. This is why Rider Tool and Manufacturing Co. provides an end-to-end fabrication and field installation service that cuts out any intermediate steps and players. By cutting down on the variables, we provide a more streamlined service that makes the client’s life easier.

Contact us to discuss your equipment manufacture and installation requirements.